StarWars robot design is somewhat "Dog-Like"

Keith Rowell Design

Phase one of the AHRC Mascot Robot project, scheduled to last one year, attempts to build a rolling robot platform for the purpose of raising intrest in robotics, our club, and our club member's talents.

The motor mount design was discussed. The virtues of using an added "plate" to attach the bracket to the gearbox was weighed against keeping the "boss stop" method that the gearbox originally used. The crux of the discussion revolves around wheather any weight is transferred to the gearbox. The general consensus is that the gearbox should "float" and that all the weight should be transferred to the wheel through the axle.

2. Articulated Frame

After discussing the modifications to the "umbrella folding baby stroller" and how to add shrouds and motors to drive articulation on such a frame, it was suggested that we abandon that frame and make one from scratch that suits our needs exactly. This sidesteps the difficulties of making the pseudo appropriate frame fit our critera, while serving as good reference material for a new design.I'll post some sketches showing some of these ideas applied to our project. I look forward to your feedback.

3. Paint

It appears that the wax (applied too soon after painting) caused the paint to crack. I didn't get many other comments about the silver painted gearboxes. Please provide some input as to aesthetic styles that you would like to explore for the mascot.

4. Reference material

I've included some references here that might provide some inspiration for our mascot's design.

Hoberman was a student of Buckminster Fuller's geodesic dome design principles, and has since created fantastic articulated shapes such as the Hoberman sphere that you may have seen in toy stores. These are amazingly complex expanding structures, definitely the kind of design I would consider to be "showing off" worthy. Here are a couple of his newest mechanical odities.

http://hoberman.com/fold/Switchkick/switchkick.htm

http://hoberman.com/fold/Braintwist/braintwist.htm

http://hoberman.com/fold/assoc/projects.htm#

http://hoberman.com/fold/sightings/clinton.jpg

Some standard off the shelf mechanical shapes:

http://www.hobbyengineering.com/SectionFR.html

http://www.beijingthc.com/conveyor_chain/carbon_steel_one_piece_chains.htm

http://www.partserver.de/frame.asp?firm=duffnorton&language=english

Mechanical linkages simulations

sphynx is an incredible spherical 4 bar linkage simulator, as is Synthetica. Try them out!

http://synthetica.eng.uci.edu:16080/~mccarthy/Synthetica1.0/Synthetica.htm

http://gram.eng.uci.edu/~mccarthy/SphinxPC/Sphinx.html

http://www.keypress.com/sketchpad/javasketchpad/about.php

http://www.brockeng.com/mechanism/index.htm

http://math2.math.nthu.edu.tw/jcchuan/java-sketchpad/jsp.html

http://www.enchantedlearning.com/physics/machines/Levers.shtml

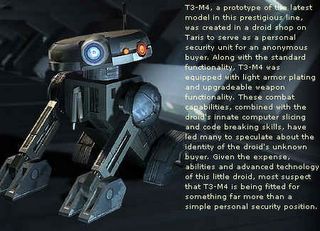

Fictitious Designs

http://www.colinmackenzie.net/robots/amee/

http://mullenmj.astromech.net/T3M4Droid.htm

Real Designs